Subscribe Newsletters

Diamond Hole Saws

SPECIFICATION

Diamond Drill Bits

| Item No. | Size | Photo | Operation method | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cutting Size (mm) | Cutting depth (mm) | Shank type | |||||||

| KW25-3050 | Ø5 | 38 | Hex shank |  |

|

||||

| KW25-3065 | Ø6.5 | ||||||||

| KW25-3080 | Ø8 | ||||||||

| KW25-3095 | Ø9.5 | Instruction | |||||||

| KW25-3127 | Ø12.7 |  |

|

|

|

|

|||

| KW25-3160 | Ø16 | ||||||||

| KW25-3190 | Ø19 | ||||||||

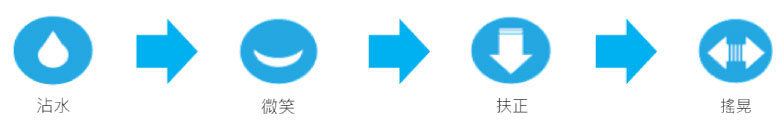

| KW25-3250 | Ø25 | S1. Dip the diamond bit into the water before cutting each hole. |

S2. Before cutting, you need to confirm that the speed of the diamond bit meets the standard value. |

S3. The diamond bit drills a surface at a 45 degree angle to the workpiece at a speed of 1500 degrees to form a smiling dent shape. |

S4. Raise the diamond bit to the vertical position and continue drilling according to the position of the smile groove shape. |

S5. The diamond drill bit is spiraled and the core will automatically pop up when the hole is completed. |

|||

※If you have special size requirements, please contact us.

Diamond Hole Saws

| Item No. | Size | Photo | Instruction | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cutting Size (mm) | Cutting depth (mm) | Shank type | |||||||

| KW25-1190 | Ø19 | 38 | 三角柄 |  |

S1.Before performing the drilling of the diamond hole saw, please refer to the corresponding specification sheet size to confirm whether the power tool speed is the standard number of revolutions. |

S2. Water must be used throughout the process to prevent each hole from overheating. If the hole is not filled with water as a lubricant, the life of the product will be greatly shortened. |

S3.The diamond bit is drilled onto the workpiece at a 45 degree angle until it assumes a concave shape. |

S4. Raise the diamond bit to the vertical position and continue drilling according to the position of the smile groove shape. |

S5. The hole is accurate with fine finish. |

| KW25-1220 | Ø22 | ||||||||

| KW25-1290 | Ø29 | ||||||||

| KW25-1320 | Ø32 | ||||||||

| KW25-1350 | Ø35 | ||||||||

| KW25-1380 | Ø38 | ||||||||

| KW25-1440 | Ø44 | ||||||||

| KW25-1510 | Ø51 | ||||||||

| KW25-1570 | Ø57 | ||||||||

| KW25-1640 | Ø64 | ||||||||

| KW25-1760 | Ø76 | ||||||||

※If you have special size requirements, please contact us.